Webfleet Cold Chain gives you complete visibility of your refrigerated fleet for worry-free cold chain logistics. With real-time temperature monitoring and control, this adaptable solution helps you both protect temperature-sensitive products and achieve cold chain compliance.

Webfleet Cold Chain helps you

Protect cargo

Monitor the temperature status of your entire fleet, on and off the road.

Save costs

React to critical situations, reduce the risk of spoiled goods and avoid costs.

Be compliant

Show customers and compliance authorities proof that there was no break in the cold chain.

Support all your vehicles

Benefit from options to receive custom temperature data, accessible on one platform.

Key features

Key features of Webfleet Cold Chain

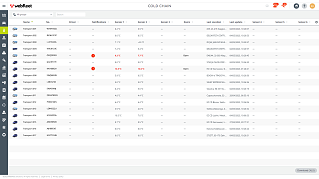

Monitor all your temperature-controlled vehicles and trailers and see their latest temperature status. Whether your fleet is transporting vaccines or temperature sensitive food goods, you can quickly validate that the cargo is at the correct temperature and minimise claims from damaged goods with the Webfleet Cold Chain solution.1

Real-time notifications

Alerts help you react to critical temperature events when a temperature in the vehicle exceeds either maximum or minimum thresholds. Temperature sensor thresholds are fully configurable. You set the thresholds based on the acceptable temperature range for cargo under your care. You’re in control.

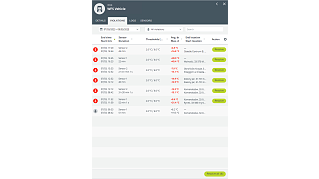

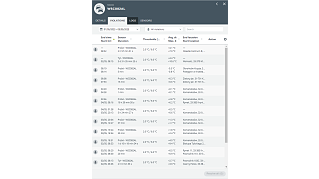

Temperature violation events

Get to the root cause of critical situations with an overview of all temperature violation events. Investigate, where and why the temperature exceeds set thresholds, and zoom into detailed event analyses by vehicle. Prevent future temperature violations with monitoring data from your cold chain transport.

Monitor doors and cooling unit status

Digital inputs show door status (OPEN/CLOSE) and cooling unit status (ON/OFF), helping you and your drivers to react quickly to situations where the cold chain could be broken. An OPEN door or OFF status can impact the temperature in your vehicle negatively and create issues for your cargo.

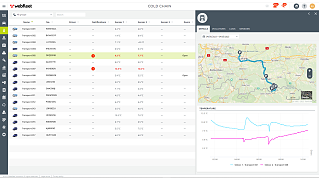

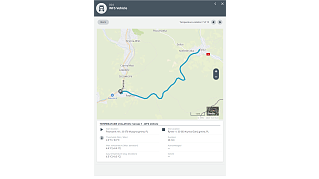

Location data

Pinpoint the exact location of temperature events to bring transparency to your cold chain operations. This information gives you insight into the temperature changes throughout your journey, which helps you determine if your cargo will still be of good quality once arriving at the destination. Understanding temperature variations is crucial for ensuring the preservation of the cargo's quality. Location information is detailed for each temperature record, along with map trace view.2

Access to historical temperature data

Temperature data is archived for up to one year and available to view directly or via downloadable reports. This gives you, your customers, and compliance authorities, the definitive proof that there was no break in the cold chain.

All you need to know about cold chain

What is cold chain?

0

What is cold chain?

0Cold chain is a supply chain that is temperature-controlled at every stage of the supply chain, from manufacturing and storage to distribution and retail. Products that involve a cold chain are for example: vaccines, chemicals, food such as fish, meats and dairy products. There are many parts to the cold chain: the factory or the farm where the goods are produced; transporting the goods to storage and transporting them onwards again for final delivery to customers. Refrigerated fleets play a vital role in maintaining the safety and quality of transported goods.

What are examples of cold chain transport?

0

What are examples of cold chain transport?

0All goods transported in the cold chain are temperature sensitive. Examples of products that require cold-chain transport include food, medicine, vaccines, chemicals, plants and medical equipment. Such goods must be transported within certain temperature ranges.

What is cold chain management?

0

What is cold chain management?

0Cold chain management is ensuring the safety and quality of temperature-sensitive products. Cold chain fleets achieve this by keeping cargo at consistent temperatures throughout the transport process. In the case of a temperature event, a fleet manager should be able to act quickly to avoid damaged goods.

What are the benefits of cold chain management?

0

What are the benefits of cold chain management?

0The main benefit of cold chain management is protecting the integrity of cargo. The wrong temperature during transport leads to damaged and rejected goods, lost profits and unhappy customers. In some cases, faulty temperatures can even pose risks to people’s health. With proper cold chain management, fleets avoid compliance issues and reputational damage.

What is cold chain logistics?

0

What is cold chain logistics?

0Cold chain logistics is a process by which the transport of temperature-sensitive goods is managed along a supply chain, from production to consumption. Cold chain fleets strive to maintain a controlled and consistent temperature environment, which ensures the quality and safety of cargo throughout transport.

How to monitor your cold chain?

0

How to monitor your cold chain?

0It’s essential to understand the root cause of a temperature issue. Otherwise, you can’t really figure out a proactive response. Getting to the root cause requires seeing where, when and why an event took place. That’s why fleets are increasingly adopting cold chain telematics, which provides real-time temperature status and vehicle location data.

Which temperatures are used in cold chain transport?

0

Which temperatures are used in cold chain transport?

0Various temperatures are used in cold chain transport. Fleets must maintain certain ranges for whatever categories of cargo they carry. For instance, the general range for frozen goods is -18°C to -20°C. The regulation of cold chain temperature rules can vary between different regions and is often influenced by factors such as climate, industry standards, and regulatory bodies. European Pharmacopoeia and WHO define temperature ranges: Deep-freeze: below -15°C, Refrigerator: 2°C to 8°C, Cold: 8°C to 15°C, Room temperature: 15°C to 25°C. Critical for product storage. Fleets must therefore stay current with the regulations for the areas in which they transport temperature-sensitive goods.

Get a demo

Find out how Webfleet Cold Chain helps you protect your temperature-sensitive cargo.

Your consent is required

In this section, external content is being embedded from .

To display the content, your consent is required for the following cookie categories:

- Targeted Advertising

- Analytics & Personalization

- Essential

For further details, please refer to our privacy policy. If you are interested in how ###vendor_name### processes your data, please visit their privacy policy.