Electric vehicles (EVs) have long been idling on the hard shoulder of fleet management conversations. But with mounting climate concerns and tightening emissions regulations, EVs have recently accelerated into the fast lane.

For fleet managers, the question is no longer if they should move over from internal combustion engine vehicles (ICEs), but how. Should it be a gradual transition or a synchronised full-fleet replacement? Making the right call requires a clear understanding of the benefits and steps involved.

The long-term gains are attractive. Switching to EVs cuts operational cuts, reduces emissions, ensures regulatory compliance and boosts brand reputation. It’s a win-win —companies profit from government incentives and stable energy prices whilst citizens enjoy quieter, cleaner cities.

There are a few steps fleet managers can take to prepare their business for a more efficient transition and start reaping those benefits.

What to consider before electrifying your fleet

Initial investment

One of the main reasons fleet managers are hesitant to electrify their fleets is the high initial cost. The lithium-ion battery needed to power an EV is relatively new technology compared with an ICE and remains expensive. The good news is, as the development of the battery advances and its production scales, the price of an EV is expected to decrease.

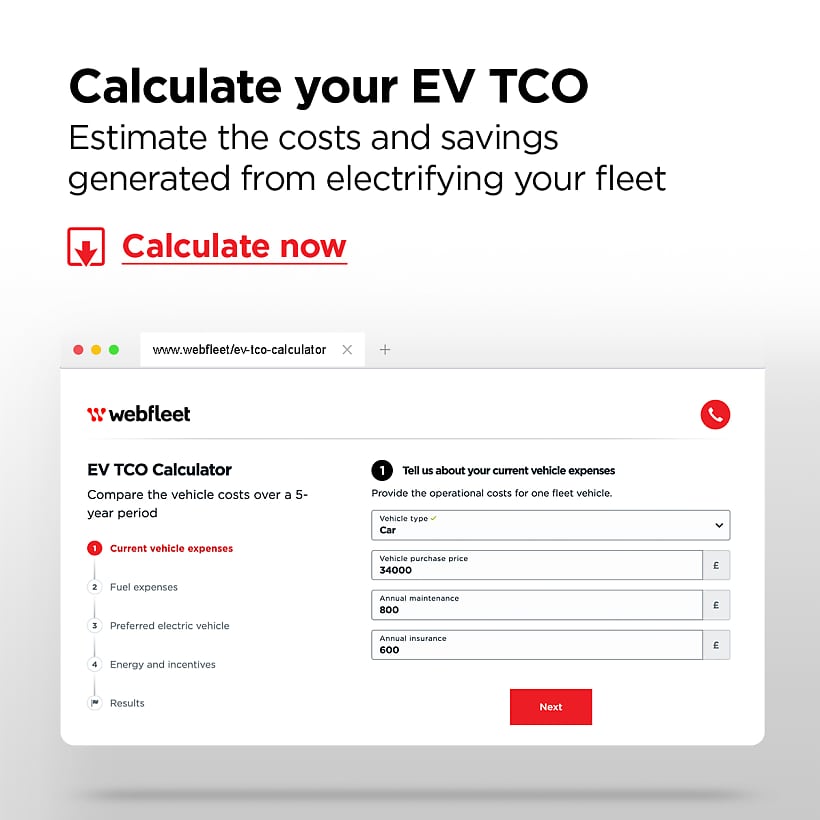

Despite the upfront investment, however, an electric fleet is far more cost-effective to run in the long term due to lower fuel and maintenance costs. Once you commit to fleet electrification, you can rest assured that your zero-emission vehicles will achieve cost parity — and, most likely, savings — over their lifespan.

Training and support

The driving mechanics of ICE vehicles and EVs are largely the same, so fleet drivers can be ‘retrained’ relatively quickly over the course of a few sessions. The key aspects to familiarise drivers with are regenerative braking, range awareness and charging instead of fueling.

Technicians, on the other hand, need to upskill further—getting up to speed with battery diagnostics and repair. Dealing with high-voltage systems also calls for knowledge of specific safety procedures.

EV maintenance training is accessible, with many manufacturers providing online and in-person programmes.

It is important for fleet businesses to seek out reliable partners to carry out maintenance in a safe, timely manner.

The steps to electrifying your fleet

Taking the leap towards EVs can be complicated for fleet managers. Planning for familiar operations with unfamiliar technology is challenging, running the risk of oversight or overspending.

To ensure a smooth transition, it’s best to consult a fleet electrification specialist like Dynamon. Dynamon outlines a three-stage plan, leveraging advanced predictive analytics technology to identify relevant insights from real world telematics and Dynamon’s proprietary EV performance database. Based on these insights, Dynamon can recommend a cost-effective transition for your fleet.

Dynamon offers a Fleet Decarbonisation Planning Report — a tailored document that delivers clear, data-driven recommendations to help you plan confidently. This report includes vehicle-by-vehicle analysis, identifies viable EV replacements or low carbon fuel alternatives, highlights suitable charging strategies and quantifies both cost savings and carbon reduction potential, giving your team a solid foundation for business case development and stakeholder engagement.

From environmental preservation to cost-efficiency, taking your fleet electric offers multiple advantages. Although a large leap, presenting challenges such as facility restructuring and range-friendly route planning, the benefits are clear and compounding. The key to a successful transition is tailoring it to your fleet — that means assessing specific vehicle needs and rooting objectives in your own data. Whether you begin with a pilot-programme or dive directly into a full-fleet replacement is up to you.